For decades, steel-toed safety boots have been synonymous with workplace foot protection in hazardous environments like construction sites, factories, and warehouses. Renowned as the undisputed gold standard for shielding against crushing impacts and penetrating objects, these boots feature a formidable steel cap integrated into the toe box. This robust reinforcement allows them to meet rigorous safety standards, typically handling impacts up to 75 pounds dropped from height and compressions exceeding 2,500 pounds. The peace of mind this level of protection offers workers facing daily hazards is invaluable.

The Unmatched Protective Shield

The core argument for steel toe cap boots remains their unparalleled defensive capabilities. In scenarios where heavy tools, machinery parts, or construction materials could fall, this steel barrier acts as a critical shield. Research underscores their effectiveness:

- A significant study cited by the National Library of Medicine ([NLM Study Link, accessible via PubMed]) investigated the outcome of a 150-pound weight dropped from three feet onto a foot. Findings revealed:

- Wearing standard shoes resulted in a high likelihood of fracture.

- Wearing safety boots with steel toes reduced the risk of fracture by a substantial 67%.

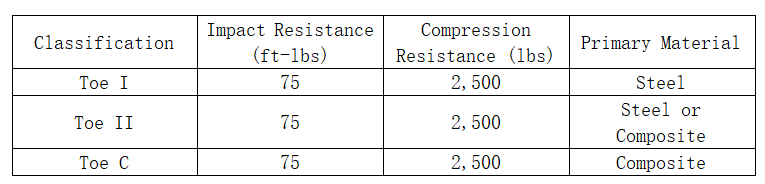

This quantifiable evidence highlights why these boots are mandated in countless high-risk professions. They form an essential, reliable barrier against catastrophic foot injuries. Modern **heavy-duty steel toe boots** are engineered to stringent standards like ASTM F2413, which defines performance levels:

Understanding Safety Toe Classifications (ASTM F2413 Standard)

(Source: Occupational Safety and Health Administration (OSHA) guidelines based on ASTM standards)

This table clarifies that both steel-reinforced toe boots (Toe I & II) and composite alternatives (Toe C & II) meet the same baseline impact/compression requirements under ASTM F2413.

Addressing the Weight Concern: Innovation Steps In

Acknowledging the critique regarding weight is crucial. Traditional steel tipped boots are indeed heavier than regular footwear or newer composite options. This extra mass can contribute to fatigue during extended shifts involving significant walking or standing. However, framing this solely as a disadvantage overlooks significant advancements:

- Material Evolution: The safety footwear industry has responded with lighter steel toe boots using advanced steel alloys and innovative boot construction techniques. While still inherently heavier than composites, the weight gap has narrowed considerably.

- The Rise of Composites: Composite safety toes (made from materials like plastic, Kevlar, or fiberglass) offer a compelling alternative. They meet the same ASTM impact and compression safety standards (Toe C or II) as steel but are significantly lighter and also non-metallic (beneficial in environments with metal detectors or electrical hazards). This provides workers with choice without compromising core safety requirements. (Explore our range of lightweight composite safety boots).

- Ergonomic Design: Modern safety boots with steel toes prioritize ergonomics far beyond older models. Features like cushioned midsoles, contoured footbeds, enhanced arch support, and flexible outsoles actively combat fatigue, making even traditional steel-toed safety boots more comfortable for long wear.

The Policy Imperative: Protection First

The debate around mandatory steel toe cap boots policies hinges on risk assessment. Employers have a fundamental duty to protect their workforce from known, severe hazards. In environments where crush or puncture injuries are a significant, foreseeable risk (like construction, heavy manufacturing, logistics warehouses), mandating safety toes – whether steel or ASTM-compliant composite – is not bureaucratic overreach; it’s a scientifically-backed necessity proven to prevent life-altering injuries. Policies should be tailored, however:

- Rigorous job hazard analysis determines if safety toes are needed.

- Worker comfort and fit are paramount – uncomfortable boots won’t be worn properly.

- Providing options, including lighter steel alloys and composite safety toes, addresses fatigue concerns while maintaining protection.

Conclusion: A Gold Standard Evolving, Not Replaced

Characterizing steel-toed safety boots as having “drawbacks” misses the broader picture. Their core strength – unmatched, proven impact and compression protection – remains vital. The weight challenge, while valid, is being successfully mitigated through material innovation, the availability of equally protective composite alternatives, and vastly improved boot ergonomics. Far from being outdated, the steel-reinforced toe boot principle remains the bedrock of foot safety in high-risk industries. It has simply evolved, offering workers and employers more choices to achieve the highest level of protection without sacrificing as much comfort. The focus should remain on selecting the right protective footwear (steel or composite) based on the specific hazards and ensuring it is worn consistently – that is the true gold standard for workplace safety.