For decades, steel toe protective boots were synonymous with heavy, clunky footwear – a necessary trade-off for workplace safety. But the rise of lightweight steel toe boots has sparked a crucial question: Can lighter alternatives truly offer the same level of protection as traditional models? The answer, backed by materials science and rigorous testing standards, is a resounding yes. Modern protective steel toe boots leverage advanced engineering to deliver uncompromised safety without the burden of excessive weight.

The Evolution of Toe Protection: Beyond Steel Alone

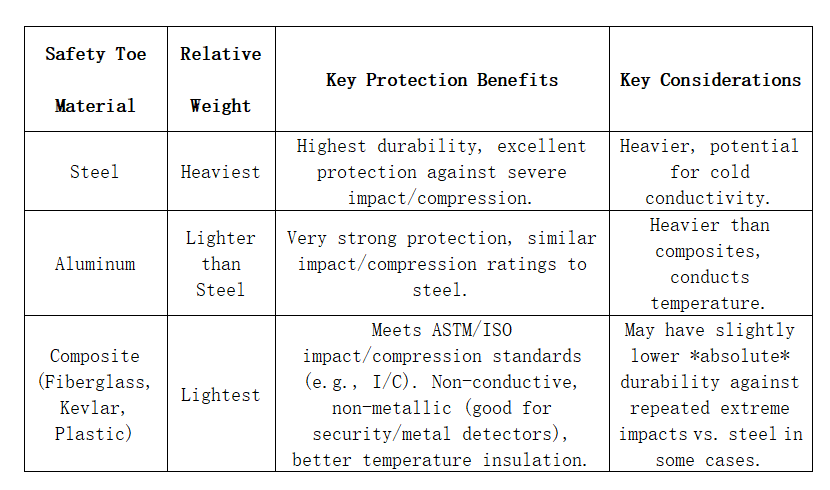

Traditional safety boots with steel toes rely on solid steel caps for impact and compression resistance. While exceptionally durable, steel’s inherent density contributes significantly to boot weight. This is where innovative materials step in:

- Composite Toe Caps: Made from materials like fiberglass, Kevlar, or plastic polymers, composite toes are significantly lighter than steel. Crucially, they meet the same rigorous impact and compression safety standards (ASTM F2412-18/2413-18 in the USA, ISO 20345 internationally) while offering additional benefits like non-conductivity and temperature insulation. Modern composite materials have closed the protection gap remarkably.

- Aluminum Toe Caps: Offering a middle ground, aluminum caps are lighter than steel but heavier than top-tier composites. They provide robust protection, similar to steel, but lack the thermal insulation properties of composites. They remain a viable lighter alternative to steel.

This evolution means safety steel toe boots no longer equate solely to heavy footwear. Boots with steel toe protection remain vital for extreme hazards, but composite and aluminum options now provide certified protection at a fraction of the weight.

Safety Standards: The Equalizer

The critical factor determining safety isn’t weight, but certification. Whether a boot uses steel, aluminum, or composite for the toe cap, it must undergo stringent testing to earn its safety rating. Key standards include:

- Impact Resistance: Measures the toe cap’s ability to withstand a heavy object dropped from height (e.g., 75 ft-lb impact force for ASTM/ISO safety toes).

- Compression Resistance: Tests the toe cap’s ability to resist crushing forces (e.g., 2,500 pounds for ASTM/ISO safety toes).

- Other Ratings: Standards also cover puncture resistance, metatarsal protection, electrical hazard rating, and more.

A lightweight steel-toe safety footwear model bearing the ASTM F2413-18 I/C (Impact/Compression) label offers the same fundamental level of impact and compression protection as a traditional steel toe boot with the same rating. The difference lies in the material technology achieving that rating more efficiently.

Lightweight Steel Toe Boots: Meeting the Standard

(Source: Summarized from ASTM International Standards F2412-18 / F2413-18 & Industry Knowledge)

Why Lightweight Matters: Beyond the Scale

The benefits of protective steel toe boots that are genuinely lightweight extend far beyond simple comfort:

- Reduced Fatigue: Lifting less weight with every step significantly decreases muscle fatigue over a long workday. The American Podiatric Medical Association highlights that heavy footwear contributes to leg and back strain. Lighter boots promote better posture and endurance, especially for those constantly on their feet (e.g., warehouse workers, nurses in specific roles, technicians).

- Improved Agility & Safety: Workers can move more freely and react faster to potential hazards. This enhanced agility can be a critical safety factor in dynamic environments like construction sites or busy workshops. Tripping hazards are also potentially reduced.

- Enhanced Comfort & Compliance: When safety boots with steel toes (or composite/aluminum) are comfortable, workers are more likely to wear them consistently and correctly, maximizing their protective benefit. Discomfort is a major reason for non-compliance with safety footwear policies. Lightweight models often incorporate better overall ergonomics and cushioning.

- Broader Application: Lightweight steel toe protective boots make safety footwear practical for roles where heavy boots were previously unsuitable or overly cumbersome, such as light industrial settings, specific healthcare environments, or even office-warehouse crossover roles.

Choosing the Right Boot for the Hazard

Selecting the best safety steel toe boots involves assessing the specific hazards of your job:

- Extreme Impact/Crush Hazards (e.g., heavy construction, mining): Traditional steel toe boots remain a top choice due to their maximum durability under repeated, severe impacts. However, high-quality composite toe boots meeting the same ASTM/ISO I/C ratings are also suitable for many tasks within these sectors and offer significant weight savings.

- General Industrial/Construction/Warehousing: Modern lightweight safety boots with composite or aluminum toes are ideal, providing certified protection, reduced fatigue, and improved mobility. They excel in these environments. (Explore our guide to choosing composite vs steel toe boots).

- Light Industrial/Electrical/Lab Settings: Composite toe boots are often the perfect solution, offering safety, lightness, non-conductivity, and better temperature comfort. They provide essential protection without the bulk of traditional designs. (Discover lightweight safety shoes for light industry).

- Environments with Security/Metal Detectors:** Composite toes are non-metallic, eliminating the need to remove boots during security checks – a significant advantage.

Modern Innovations Enhancing Both Safety and Comfort

Today’s top-tier protective steel toe boots, especially lightweight models, incorporate features that enhance both protection and wearability:

- Advanced Midsole Materials: Technologies like PU, TPU, or specialized EVA offer superior cushioning, energy return, and longevity while keeping weight down.

- Anatomical Design & Ergonomic Insoles: Contoured footbeds and supportive arches improve comfort and reduce foot fatigue dramatically.

- Breathable & Waterproof Membranes: Materials like GORE-TEX® allow feet to breathe while keeping water out, enhancing comfort in diverse climates.

- Slip-Resistant Outsoles: Advanced rubber compounds provide superior traction on oil, water, and other slippery surfaces – a critical safety feature often integrated seamlessly.

- Quick Lace Systems: Improve convenience, allow for micro-adjustments for better support and circulation, and enhance safety by preventing loose laces.

Conclusion: Safety Isn’t Measured in Pounds

The evidence is clear: Lightweight steel toe boots engineered with modern composite or aluminum materials and certified to recognized safety standards (ASTM, ISO) provide impact and compression protection equal to their heavier steel counterparts. The significant reduction in weight translates directly into tangible benefits: reduced worker fatigue, improved agility and reaction times, enhanced overall comfort, and greater willingness to wear the boots consistently. While traditional boots with steel toe protection retain their place in ultra-high-impact scenarios, for the vast majority of industrial and hazardous workplaces, modern lightweight steel-toe safety footwear offers an equally safe, significantly more comfortable, and ultimately more productive solution. When choosing, prioritize the ASTM/ISO safety rating appropriate for your hazards over the material alone – certified lightweight safety boots with steel toes (or composite/aluminum equivalents) deliver safety without the unnecessary burden. (Learn more about workplace safety footwear regulations on OSHA’s website).